If you’re someone who wishes to gift different goodies to friends or business partners, or even your family and distant relatives, you definitely want to make sure that you offer food with good packaging.

Nougats are a great dessert that people can enjoy, and if you’ve thought about doing this, you want to make sure that you offer a unique holiday packaging. Even if it’s just a sleeve or box that’s special, you can add it there, without too many different changes to the orders or quantities.

You can get a lot of different types of packaging options. Probably one of the most common is the one that everyone’s seen their grandparents have. There’s the little bowl that’s silver, and then, with a doily sitting right under it, a bunch of nougats or other types of candies that are there.

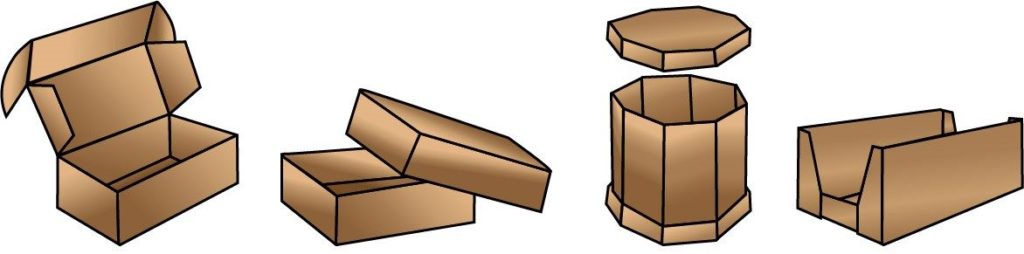

While the candies themselves stand the test of time, the packaging does change. One of the most popular is the rollover lid box that’s hinged, and it’s great for offering a great, inviting sort of means to the products. This is something that’s great for convincing just about anyone that hey, these candies are great.

Another fun one to get for these is what’s called a gable top box, and this is one that’s great for nougats especially. It’s cool too because you can add photographic images, with different color gradients for the background that’s there. Adding the strap that’s integrated near the bottom does offer a highlight to the taste, and that, along with the logo that’s put on there in different colors, really completes the look. It offers a look that’s simple, elegant, but isn’t considered minimalist. This is something that’s good too in order to shout from the store shelf that people should get this, so it’ll help with packaging sales too.

Another one for those selling nougats in stores is a display box. This is one that’s basic and also usually is pretty simple for people to understand. They’re usually confined to a flap that’s in the upper area, with different references within the main body. The bottom half of it is also convenient too for the sole purpose of picking up and having the product. Again, while simple, it’s enough to convince others that this product is so worth it.

If you’re trying to make a package that does house candies that are different in sizes, then you’ll want to consider a sleeve that’s capable of getting the eye of the consumer’s, and also giving different indications of the brand and product, along with information displayed such as the ingredients that are used, different nutritional information and values. The graphics are simple, but they’re lively, since most of this does focus there, and the colors are both usual, and vivid too. This is good for small items such as nougats, but also snacks and biscuits that you can enjoy too.

Finally, if you’re trying to bring out the real fancy nougats, then you want to get a double walled tray for this. This is one that’s great since it doesn’t need to have a lid on, since the nougats get put in plastic wrapping. This is great because it protects the items that are there, makes them important, and also frames just how pretty the ingredients are. The artwork does disappear, but it does offer a nice, refreshing touch.

In general, giving the proper casing for nougats is important, and with this casing, you’ll be able to, with this, create a splash and a bunch of different effects that you wish to create.